... AND MORE Products

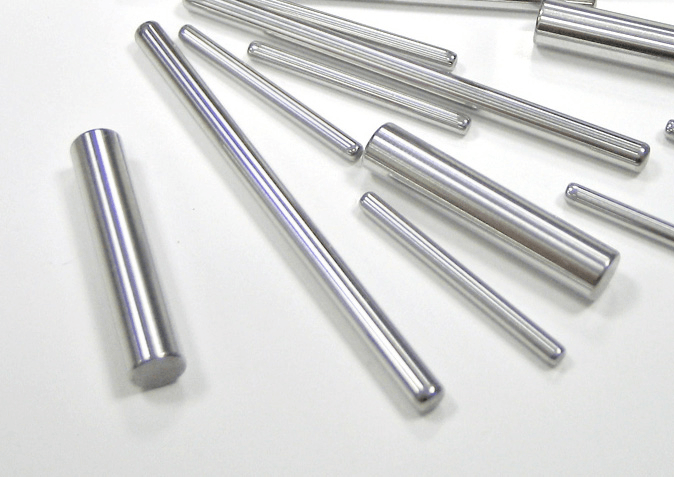

ROLLERS - PINS - SHAFT

Rollers, pins and shafts have multiple uses.

They are built with a diameter tapered at the ends to avoid the load concentrations of the rolling elements, concentrations determined by the load on the bearing and by the deflections of the shaft.

They are used for example in electric motors, gearmotors, and locks

UNI 100 Cr6 hardened and tempered is the most used material, but we can supply them in AISI 420A hardened, AISI 420C hardened, AISI 316, 302 and 304 as well as in C72 and C80

They can be supplied both with rounded head and with sheared head, and can be made according to the most varied requirements. We can also supply rollers with a degree of precision in class G2 (2 microns) and G5 (5 microns) with roundness tolerances of 1 and 2.5 microns respectively.

SINTERED FILTERS IN STAINLESS STEEL AND BRONZE, SILENCERS IN BRONZE AND MOLDED ACETAL RESIN

The wide range of achievements involves the most diverse sectors and companies: the automotive sector, manufacturers of agricultural machinery, pumps, gearboxes, electronic and electromechanical mechanisms, couplings, gears.

THE MATERIALS USED ARE: BRONZE, IRON, CARBON STEEL

Parts with different blends of powders are available.

The pieces can be subjected to further treatments such as impregnation in anti-rust, for a long-lasting storage and vaporization, which allows a better surface hardening), galvanizing and nickel plating.

For demanding applications, carbonitriding and hardening are carried out.

In a very short time, we provide cost estimates for the individual equipment and the particular to be made.

Quality